Our services at a glance

- Consultation

- Engineering

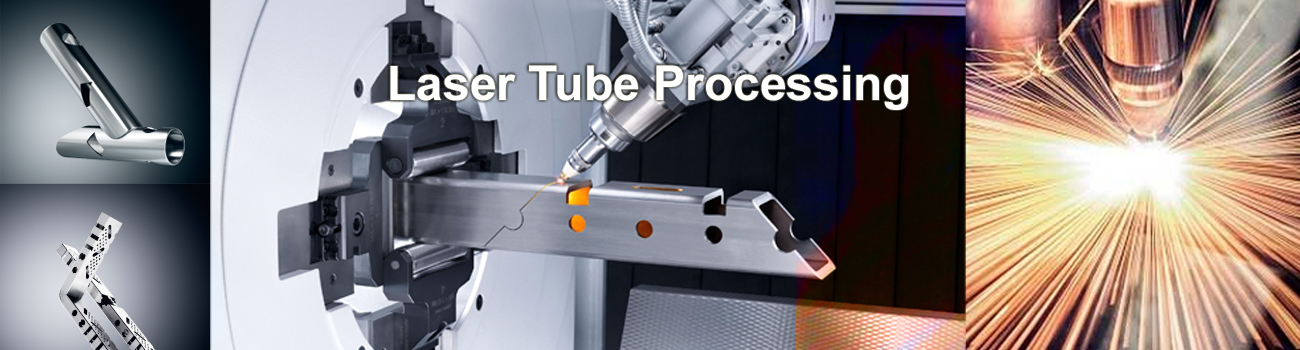

- Tube laser processing

- Tube laser processing with 3D cutting

- Tube laser processing with flow form thread, thread etc.

- Manufacture welded assemblies (MIG / MAG, TIG)

- Powder coating on the in-house facility

- Module assembly

- Delivery with our own fleet

Technical specifications

- Profile types: round, square, rectangle, oval

- Special profiles: individual test necessary

- Cutting capacity steel: 8 mm (thicker materials on request)

- Cutting capacity stainless steel: 6 mm (thicker materials on request)

- Cutting capacity aluminum alloys: 5 mm (thicker materials on request)

- Finished part length max .: 6,000 mm

- Enveloping circle diameter max .: 204 mm

Our expertise in tube processing is a real competitive advantage for you. We guarantee this through decades of experience in conventional tube processing and are expanding this competence with a new, ultra-modern and flexible tube laser center. With this tube laser center, we can efficiently and competitively produce individual parts as well as series parts for you. Our tube laser center is equipped with an additional tool changer, so we can laser cut your orders with a previously unachievable efficiency and provide the workpiece with flow bores, threads, countersinks and more in parallel The competence available to you does not end with the mere tube laser processing. If necessary, we will be happy to join entire welded assemblies for you with our certified welders. The quality is secured internally by the in-house production control. Regular external audits confirm our high quality standard. Therefore, MAW GmbH has been certified according to DIN EN-1090 EXC2 since 2014.

Our prospectus can be viewed and downloaded here

English

English  German

German