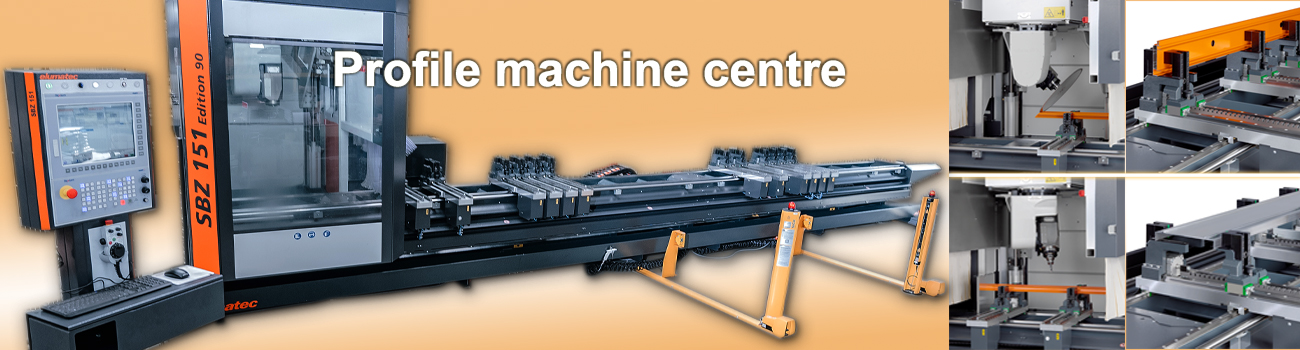

SBZ 151 Edition 90 Aluminum bar machining centre

Our services at a glance

- Consultation

- Engineering

- Profile machining with routing, drilling, tapping, thread milling, notching and sawing

- Powder coating on the in-house facility

- Module assembly

- Delivery with our own fleet

Description

- 5-axis aluminum bar machining center

- Designed for flexible and efficient machining of aluminium and thin-walled steel profiles

- All operations, such as routing, drilling, tapping, thread milling, notching and sawing, are performed while the profile bar is stationary to protect the profile surfaces

- Fast positioning of the machining unit with up to 66 m/min thanks to dynamic servo drives

- The on-board tool magazines ensure that tool changing times are kept short, thereby optimizing machining cycles

- One magazine can be equipped with 13 standard tools and seven special tools (angle routing head and special cutters). An additional magazine for the saw blade, diameter 500 mm

- Autonomous clamp positioning with absolute measurement system

- Two separate working zones enable machining in shuttle operation.

Technical specifications

SBZ 151 Edition 90 - 7.3 m

- Max. machining length with profile end machining, 6,980 mm

- Max. machining length without profile end machining, 7,300 mm

- X-axis traverse path 7,300 mm, Vmax. 66 m/min.

- Y-axis traverse path 1,150 mm, Vmax. 40 m/min.

- Z-axis traverse path 715 mm, Vmax. 40 m/min.

-

- Pivoting angle A-axis (for saw blade with diameter of 500 mm) +/- 100°

- C-axis pivoting angle +/- 182°

- Positioning accuracy

- X-/Y-/Z-axis +/- 0.1 mm/m

- A-/C-axis +/- 0.1°

Our expertise in aluminum bar machining is a real competitive advantage for you. We guarantee this through decades of experience in conventional aluminum bar machining and are expanding this competence with a new, ultra-modern and flexible aluminum bar machining centre. With this machining centre, we can efficiently and competitively produce individual parts as well as series parts for you. Our aluminum bar machining centre is equipped with an additional tool changer. So we cut your orders with a previously unachievable efficiency and provide the workpiece with flow bores, threads, countersinks and more in parallel. The competence available to you does not end with pure profile processing. If required, we will be happy to assemble entire assembly groups for you and also offer you powder coating on our in-house system. The quality is secured internally by the in-house production control. Regular external audits confirm our high quality standard. Therefore, MAW GmbH has been certified according to DIN EN-1090 EXC2 since 2014.

Our prospectus can be viewed and downloaded here

English

English  German

German